Basic Info.

Model NO.

DSP-80KW

Test Report

Provided

Features

Don′t Need Water to Cooling , Easy to Operate

Display

Digital Screen Display

Transport Package

Export Wooden Box Packing

Specification

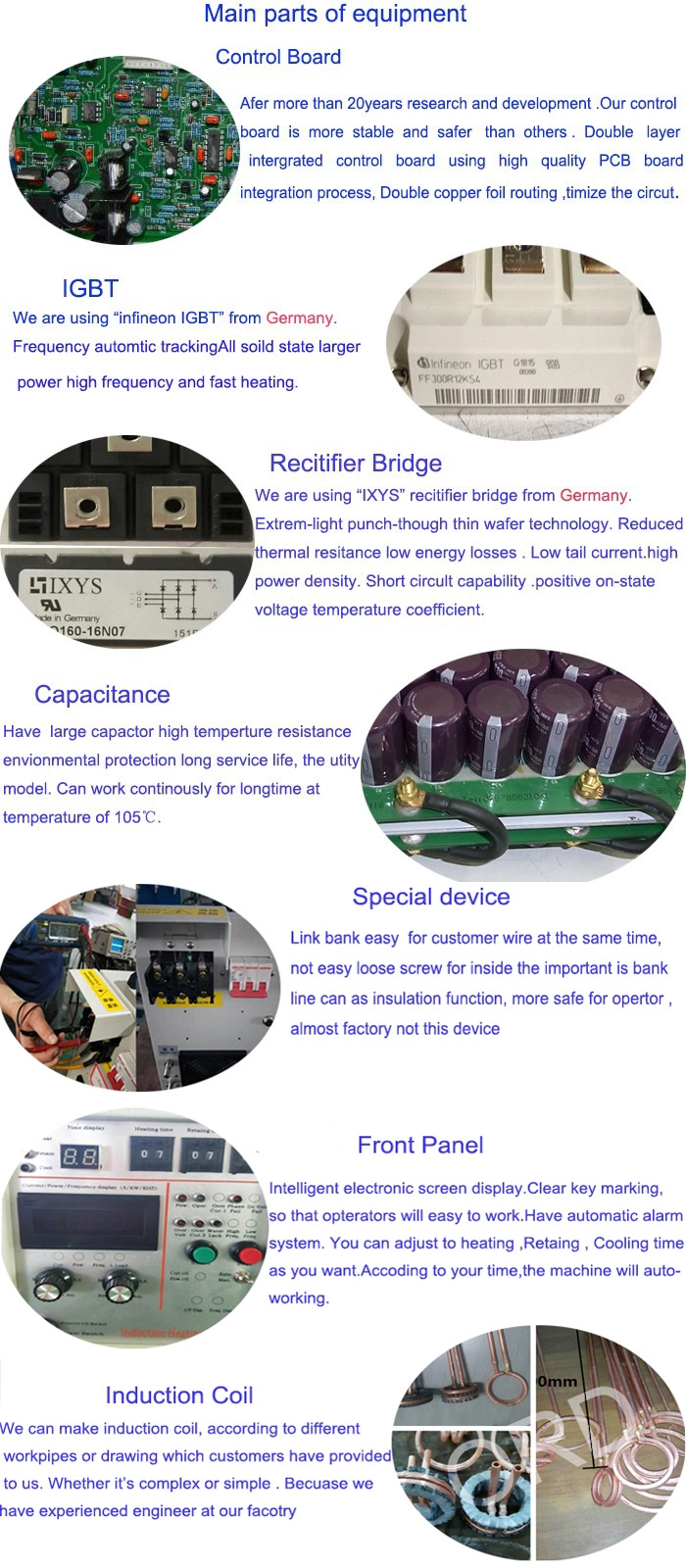

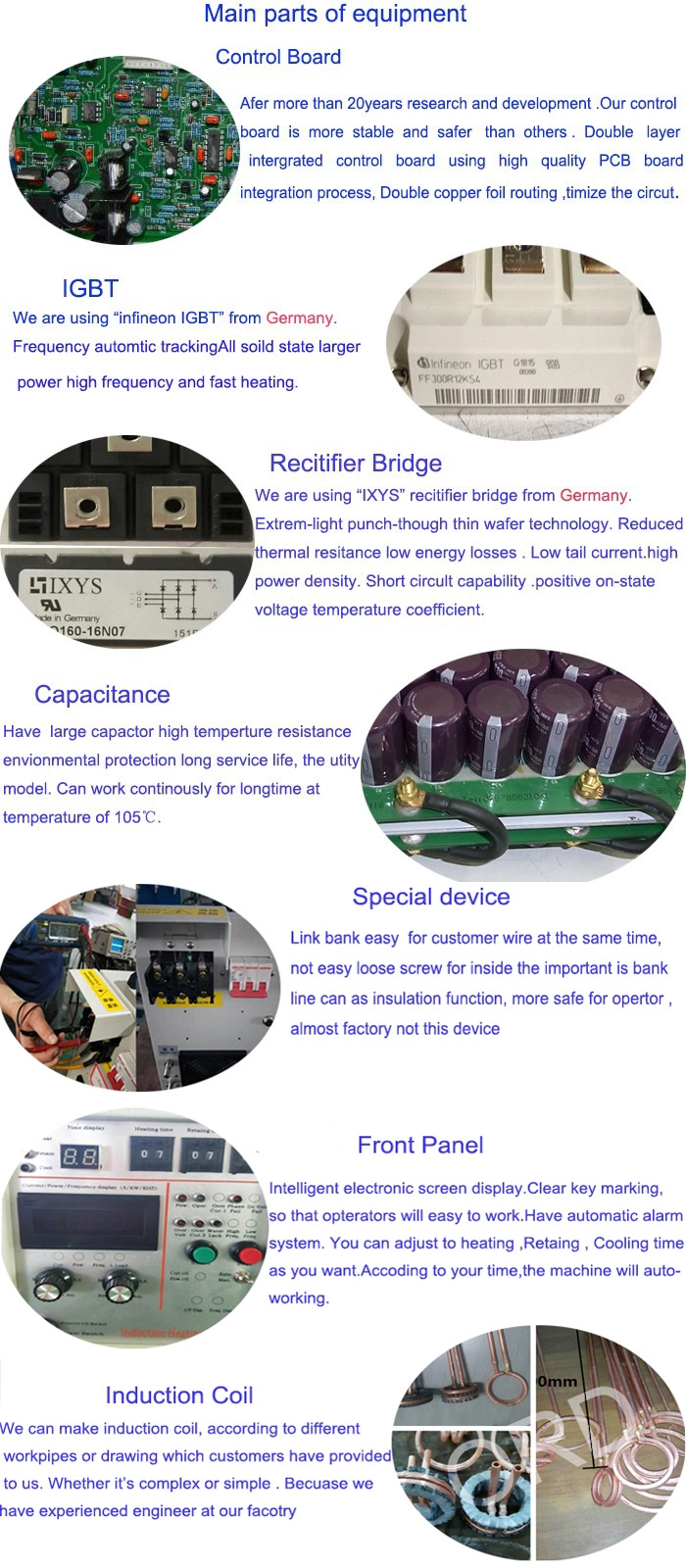

IGBT

Trademark

OURUIDA

Origin

China

HS Code

8514400090

Production Capacity

6000/Month

Product Description

China Manufacturer Supply Air cooling system IGBT Digital Induction heating machine for Preheating of pipes or workpieces, dehydrogenation (DSP-80KW)

Maintains the normal properties of all bamac-atec series induction heating generators.

Has 18 branch series, hundreds of specifications and models of the product group.

It has the largest application performance of 1200KW air cooling induction heating generator in the world, and the manufacturing

technology of 300kW air cooling induction generators andinductor.

It has hundreds of well-known enterprise users, including more than 20 users of the world's top 500 enterprises, more than 40 users of listed companies at home and abroad,

All series DSP core control strategy of power supply upgrade for "reactance method",which become more and more perfect slam the door before the tabernacle "lock 90 cycle", therefore, to eradicate the insurmountable defects,before many enhancements.

Process PID temperature closed loop control program, oriented to the workpiece and process, to achieve stable temperature control without overshoot.Stable and perfect temperature control can be realized from extremely small workpiece to extremely large workpiece, from fast to 1s to slow to dozens of days.

Full series with energy control function.:

The whole series is equipped with the function of "insulation resistance online monitoring and protection", which provides an effective guarantee for personal safety.

High reliability design and stringent factory assembly, testing,aging and removal of unstable components,each power source has months of continuous high power uninterrupted operation ability.

The customization and rich setting functions and a variety of operating control mode enable OURUIDA 's induction heating equipment suitable for almost all induction heating process requirements.

Electromagnetic radiation,power grid harmonics, electromagnetic compatibility in accordance with the national standards and IEC standards, no harm to human body, power grid harmonics, do not affect the operation of other equipment (with all certificate issued by Germany TUV). Fully air-cooled generators have a design life of 20 years.

Always uphold the high - tech, energy - efficient, high - reliability of the product concept. It also promises to ensure that each power supply can operate normally in its service life.

The mian Freatures:

1.Fully air-cooled Structure

Completely eliminate water system failure, lower loss, higher reliability;Air - cooled inductor can be used in some conditions

2.DSP main processor, full digital product

3.PID temperature closed-loop control program that designed for prodution process and workpiece can achieve stable temperature control without overshdot

Capable of heating workpieces ranging from a few grams to several hu

With an inert link transfer function, it can solve the problem of n Ttemperature signal and realize automatic temperature control without overshoo

The rate of temperature change is controllable

Rich enhancements and options for a variety of industrial occasions.

4.Rapid VS Slow: Second level fast temperature control VS A slow rate of temperature change over several days

Perfect match for fast cycle time control of production line

Full range of temperature change rate can be set from 0.1 C/H-1600 °C/S.

5.PID parameter automatic setting function,the realization of professional temperature control can not need professional theoretical knowledge of automatic control.

6.Energy control

The energy applied to the workpiece can be controlled and based on this energy temperature control, restriction and protection can be caied out to meet the requirements of high-level and complex

7.Accurate and fast internal control

When the output current measurement and control resolution reaches 0.1A,the output is stable and unfluctuating,and the control speed is not affected.

8.Insulation resistance online monitoring

Runtime real-time insulation resistance measurement circuit and display and can be set up and implement protection.

9.Fast automatic phase-frequency tracking technoloa based on reactalice anaiysis

Solve the problems of "lock90-cycle" such as phase instability, frequency deviation, capacitive switching, and narrow tracking range and so on.

The switching loss of IGBT can be reduced by more than 30% at high frequency.

Within 10 times of designed frequency range of device can accurately track and maintain the IGBT zero switch.

10.Four basic operating modes

Constant current operation, Constant power operation, Constant temperature operation, Process program operation (The last two are optional)

Each operation mode can be combined with energy control,timing, fast cycle control and other functions.

11.Process program operation module (optional)

Allows users to preset temperature curves to complete complex heat treatment processes or heating process requirements.

There are 16 process programs can be preset, that each process program can be programmed for

11.Process program operation module (optional)

Allows users to preset temperature curves to complete con stment processes process requirements.

There are 16 process programs can be preset, that each process program can be progra dozens of running segments and each segment can be timed.

Based on the process type of PID temperature control program, the new process program is greatly.It improves the safety and reliability of the process program, improves the marinterface.The machine precision is improved and the heating curve joins smoothly.All s wider: single period of time from 0.1 S - 115 days, the temperature change rate from 0.1 C/ H/ S full range can be set, constant current and constant power can set the changing rate of c power.

12.Built in 1-6 temperature transmitters (optional)

The type and range of the temperature transmitter can be customized.When multi points tem are measured, the device will automatically select the highest temperature point for tem control. The device has the function of multi-point over temperature difference alarm ar preservation operation after the temperature difference.

13.Fast cycle running control mode

A special fast cycle control mode is set up. The start/stop time of the current rise/fall can be as

0.2s, and the 1s level cycle control can be achieved.

14.Air cooled inductor temperature limit function

Protects the air-cooled inductor from overheating damage, and maximizes the transient load rate of th induction heating system.

15.Magnetic flux limiting function

Avoid magnetic saturation of transformer core, transformer damage and over current protection.

16.Fast IGBT drive circuit

Obviously improve the resonance waveform and reduce the dead time. Further reduce the switching loss and increase the stability of high frequency tracking.At the same time each IGBT drive has short circuit protection and under voltage protection.

17.High reliability design and stringent factory assembly and testing

Each power supply has been tested at Bamac plant for high-power operation,aging and removing unstable components, so as to ensure that each power supply has the capability of continuous high- power operation for months without interruption.

18.Uninterrupted operation design

In the case of quick cut or flicker of the power supply circuit or accidental protection, the device can make automatic diagnosis and automatically return to normal operation state (automatic restart) to avoid production loss caused by shutdown.

19.Wide range of grid voltage adaptation

Under the control of DSP, the output operation value is not affected by the voltage fluctuation of the power grid.

Our Company photo:

Feedback from clients:

Maintains the normal properties of all bamac-atec series induction heating generators.

Has 18 branch series, hundreds of specifications and models of the product group.

It has the largest application performance of 1200KW air cooling induction heating generator in the world, and the manufacturing

technology of 300kW air cooling induction generators andinductor.

It has hundreds of well-known enterprise users, including more than 20 users of the world's top 500 enterprises, more than 40 users of listed companies at home and abroad,

All series DSP core control strategy of power supply upgrade for "reactance method",which become more and more perfect slam the door before the tabernacle "lock 90 cycle", therefore, to eradicate the insurmountable defects,before many enhancements.

Process PID temperature closed loop control program, oriented to the workpiece and process, to achieve stable temperature control without overshoot.Stable and perfect temperature control can be realized from extremely small workpiece to extremely large workpiece, from fast to 1s to slow to dozens of days.

Full series with energy control function.:

The whole series is equipped with the function of "insulation resistance online monitoring and protection", which provides an effective guarantee for personal safety.

High reliability design and stringent factory assembly, testing,aging and removal of unstable components,each power source has months of continuous high power uninterrupted operation ability.

The customization and rich setting functions and a variety of operating control mode enable OURUIDA 's induction heating equipment suitable for almost all induction heating process requirements.

Electromagnetic radiation,power grid harmonics, electromagnetic compatibility in accordance with the national standards and IEC standards, no harm to human body, power grid harmonics, do not affect the operation of other equipment (with all certificate issued by Germany TUV). Fully air-cooled generators have a design life of 20 years.

Always uphold the high - tech, energy - efficient, high - reliability of the product concept. It also promises to ensure that each power supply can operate normally in its service life.

The mian Freatures:

1.Fully air-cooled Structure

Completely eliminate water system failure, lower loss, higher reliability;Air - cooled inductor can be used in some conditions

2.DSP main processor, full digital product

3.PID temperature closed-loop control program that designed for prodution process and workpiece can achieve stable temperature control without overshdot

Capable of heating workpieces ranging from a few grams to several hu

With an inert link transfer function, it can solve the problem of n Ttemperature signal and realize automatic temperature control without overshoo

The rate of temperature change is controllable

Rich enhancements and options for a variety of industrial occasions.

4.Rapid VS Slow: Second level fast temperature control VS A slow rate of temperature change over several days

Perfect match for fast cycle time control of production line

Full range of temperature change rate can be set from 0.1 C/H-1600 °C/S.

5.PID parameter automatic setting function,the realization of professional temperature control can not need professional theoretical knowledge of automatic control.

6.Energy control

The energy applied to the workpiece can be controlled and based on this energy temperature control, restriction and protection can be caied out to meet the requirements of high-level and complex

7.Accurate and fast internal control

When the output current measurement and control resolution reaches 0.1A,the output is stable and unfluctuating,and the control speed is not affected.

8.Insulation resistance online monitoring

Runtime real-time insulation resistance measurement circuit and display and can be set up and implement protection.

9.Fast automatic phase-frequency tracking technoloa based on reactalice anaiysis

Solve the problems of "lock90-cycle" such as phase instability, frequency deviation, capacitive switching, and narrow tracking range and so on.

The switching loss of IGBT can be reduced by more than 30% at high frequency.

Within 10 times of designed frequency range of device can accurately track and maintain the IGBT zero switch.

10.Four basic operating modes

Constant current operation, Constant power operation, Constant temperature operation, Process program operation (The last two are optional)

Each operation mode can be combined with energy control,timing, fast cycle control and other functions.

11.Process program operation module (optional)

Allows users to preset temperature curves to complete complex heat treatment processes or heating process requirements.

There are 16 process programs can be preset, that each process program can be programmed for

11.Process program operation module (optional)

Allows users to preset temperature curves to complete con stment processes process requirements.

There are 16 process programs can be preset, that each process program can be progra dozens of running segments and each segment can be timed.

Based on the process type of PID temperature control program, the new process program is greatly.It improves the safety and reliability of the process program, improves the marinterface.The machine precision is improved and the heating curve joins smoothly.All s wider: single period of time from 0.1 S - 115 days, the temperature change rate from 0.1 C/ H/ S full range can be set, constant current and constant power can set the changing rate of c power.

12.Built in 1-6 temperature transmitters (optional)

The type and range of the temperature transmitter can be customized.When multi points tem are measured, the device will automatically select the highest temperature point for tem control. The device has the function of multi-point over temperature difference alarm ar preservation operation after the temperature difference.

13.Fast cycle running control mode

A special fast cycle control mode is set up. The start/stop time of the current rise/fall can be as

0.2s, and the 1s level cycle control can be achieved.

14.Air cooled inductor temperature limit function

Protects the air-cooled inductor from overheating damage, and maximizes the transient load rate of th induction heating system.

15.Magnetic flux limiting function

Avoid magnetic saturation of transformer core, transformer damage and over current protection.

16.Fast IGBT drive circuit

Obviously improve the resonance waveform and reduce the dead time. Further reduce the switching loss and increase the stability of high frequency tracking.At the same time each IGBT drive has short circuit protection and under voltage protection.

17.High reliability design and stringent factory assembly and testing

Each power supply has been tested at Bamac plant for high-power operation,aging and removing unstable components, so as to ensure that each power supply has the capability of continuous high- power operation for months without interruption.

18.Uninterrupted operation design

In the case of quick cut or flicker of the power supply circuit or accidental protection, the device can make automatic diagnosis and automatically return to normal operation state (automatic restart) to avoid production loss caused by shutdown.

19.Wide range of grid voltage adaptation

Under the control of DSP, the output operation value is not affected by the voltage fluctuation of the power grid.

Our Company photo:

Feedback from clients: