Basic Info.

Product Description

Machine Picture:

Technical Specifications:

Wire Diameter 2.0-4.0mm

Cutting Length Range:80mm and above

Wire Feeding Speed:80m-150m/min (The faster the smaller wire diameter)

Length Tolerance:±0.5mm

Straightening Wire Material:Common Carbon Steel Wire

Wire Decoiler:1000*300*150mm

Wire Feeding Servo Motor:1.5kw with Reducer

Straightening Servo Motor:Specially made Speed Adjustable Motor

Wire Cutting Servo Motor: Servo Motor

Guide Module: Taiwan

Wire Feeding Group:2 Group (4 couplings)

Control Screen:Touch Screen

Straightening Block No.:8 pcs

Wire Material Range 2.0-4.0mm(Common Carbon Steel)

Machine Dimension:2670*710*1450(mm)

Machine Weight: 500kgs

Power supply: 3Phases, 380V, 50HZ

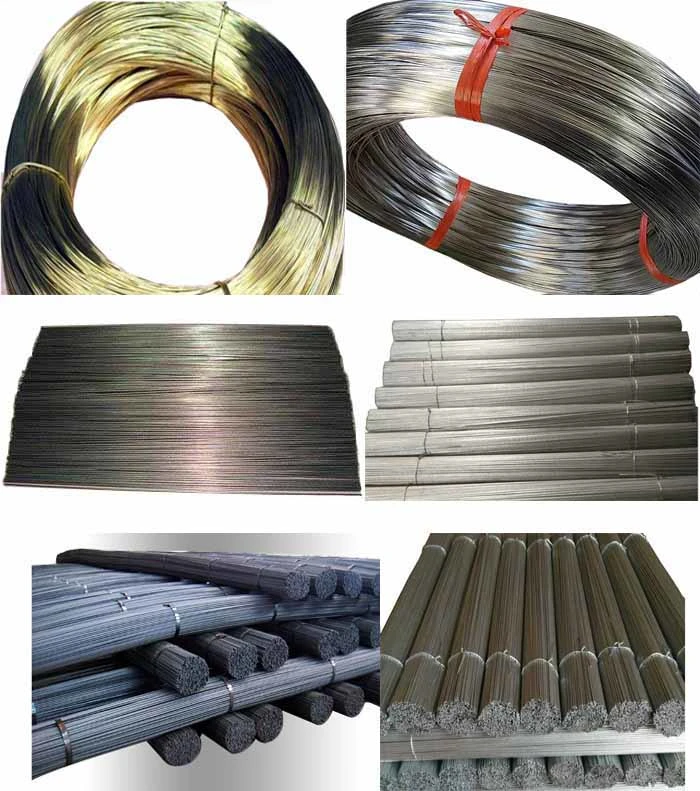

Products

Attention:

The finished product container can be custom made.

Action Sequence:

1. Manually feed wire: Manually loosen coding handwheel and pressbutton of manual wire feeding, the wire will be transmitted to front wire feeding wheels, straighten wheels, coding wheels, rear wire feeding wheels for cutting position. Then manually tighten coding handwheel.

2. Preset cutting length, speed, parameters and press button ON, the machine will work automatically.

Control System:

Wire feeding servo motor 0.55kw and cutting servo motor 0.75kw, using brand SANYO servo motor for wire feeding, straightening and cutting.

Our Workshop:

Our vision:

We are factory manufacturer located in FoShan. We have been working hard to provide reliable

quality machine with reasonable price and qualified service for our worldwide customers!

Packaging and Shipping:

Our Advantages:

We have professional teams experting in production, design and R&D for over 10 years to meet

clients' different demands.

High precison and excellent performance for producing all kinds of springs and wire forms, Japanese

Panasonic servo motor for each machine.

Machine test run(at least for one week) before we ship the machine, in an effort to insure every

mechanical and electrical parts are in perfect condition.

After order placed, we accept to adjust the products according to customer's demand, and remain

the program and tool settings on machine. in order to insure a quick start of machine once customer

receive it.

Our Certificates:

As a professional wire processing machinery manufacturer, we will try our best to supply you not only

high quality machine with very competitive price, but also in good service.

We also hope we can make friendly cooperation with you!

FAQ:

Q1: What does your factory produce ?

A: We produce and export all kinds of automatic wire processing machine. We also can design and

develop the wire processing machines according to your requirements.

Q2: What about your standard delivery date ?

A: Usually 20 days.

Q3: Does your factory sale directly ?

A: Yes. Our factory sells directly,competitive price with high quality and excellent after-sale service.

Our quality products have been export to many countries, such as Germany, Russia, USA, Canada,

Argentina, Peru, Turkey, Iran, Brazil, Spain, South Asia and Middle East countries.

Q4: Can you export machines by your factory?

A: Yes,we can.

Q5: Where are your factory?

A: Our factory is located in FoShan City and DongGuan city, Guangdong Province, China.

Q6: Will you send engineer to help installing the machine?

A : Yes, if you need, we can send our engineer to go to your factory to help you install our machine,

train the workers and make sure the welding machine running well before he leaves.

Q7: If the machine get damaged, what can I do ?

A: In the guarantee time (1 year) , we will send the spare parts to you for free and provide the

technical consultant for anytime. If more terrible, we can send our engineers to your factory.

We will provide same good after-sale service as the pre-sale service. For any of your questions,

we will reply within 12 hours.

Contact us: