Basic Info.

Model NO.

GLT-40

Transport Package

Standard Package by Sea

Specification

according to client need

Trademark

RONEN

Origin

Wuxi

Product Description

Product Description

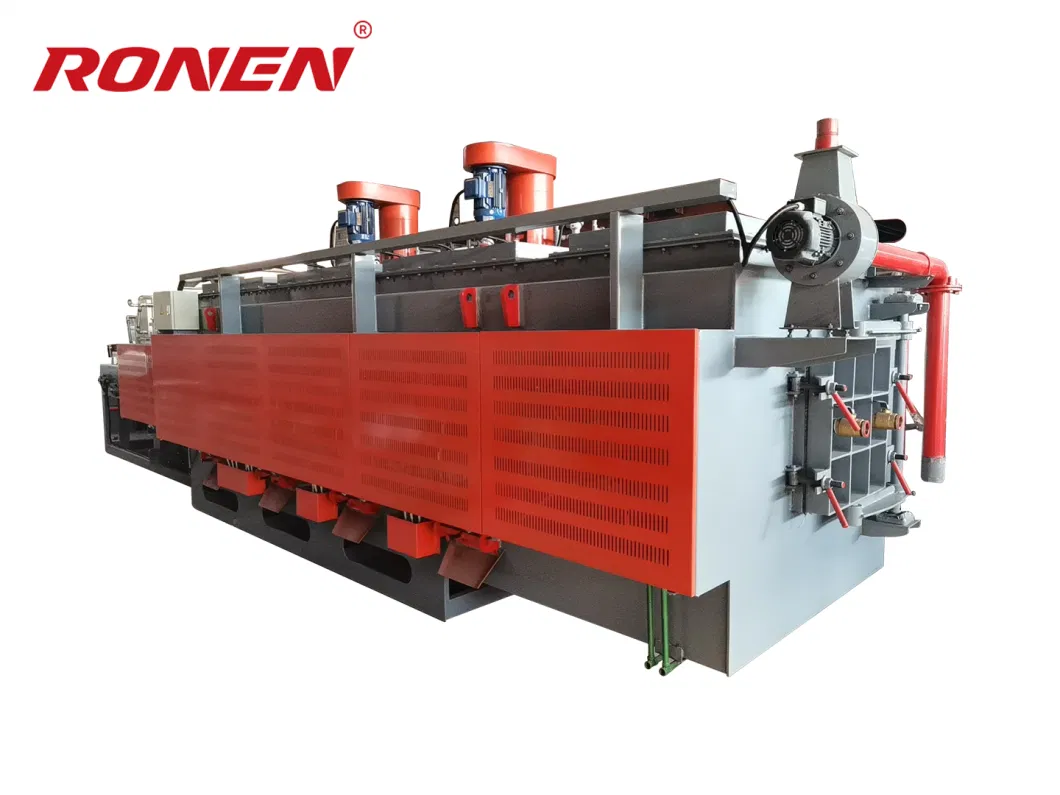

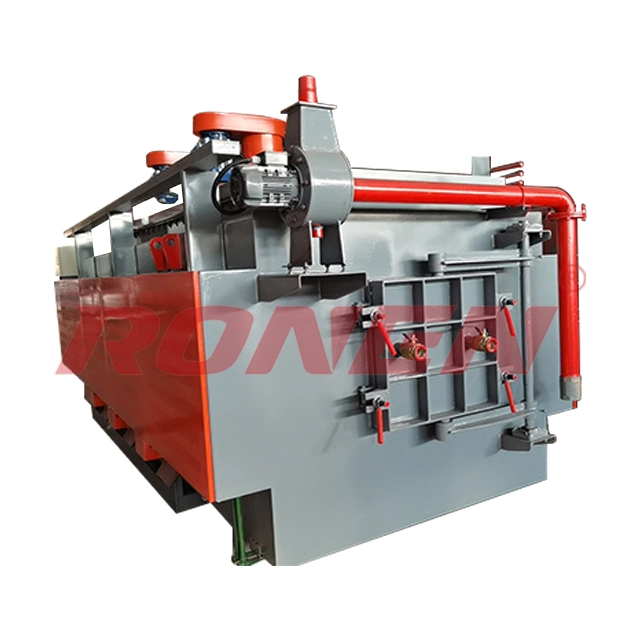

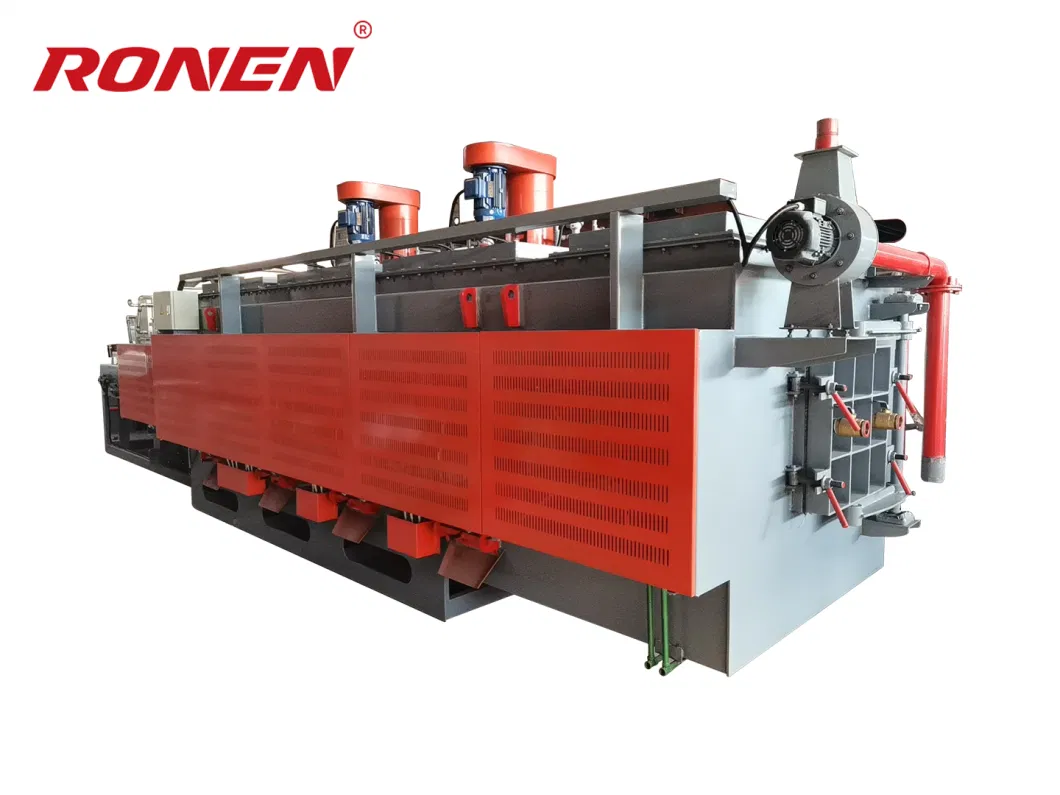

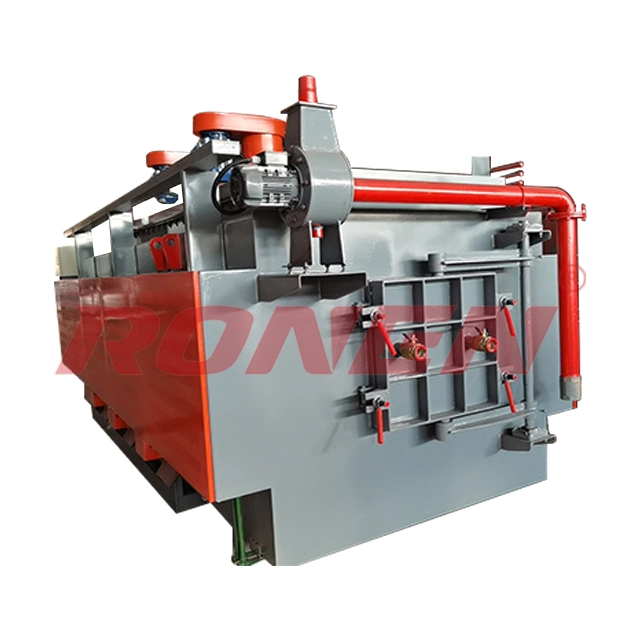

Continuous Stainless Steel Tube And Wire Mesh Belt Conveyor Bright Annealing Furnace

Annealing Heat Treatment Stove

Continuous Mesh Belt Furnace Produce

Hardening Tempering Industrial Oven

Machine Photo Show

Continuous Stainless Steel Tube And Wire Mesh Belt Conveyor Bright Annealing Furnace Photos

Our Partner Show

Our Partner Show

Continuous Stainless Steel Tube And Wire Mesh Belt Conveyor Bright Annealing Furnace

Annealing Heat Treatment Stove

Continuous Mesh Belt Furnace Produce

Hardening Tempering Industrial Oven

Machine Photo Show

Continuous Stainless Steel Tube And Wire Mesh Belt Conveyor Bright Annealing Furnace Photos

Product Description

Application of the Heat Treatment Furnace: Sealing, metalizing, brazing, oxidizing, and annealing in protective atmosphere for chip bonding, electronic packaging and the production of HTCC, DBC, VFD, PDP, auto radiators, etc.

Features of the Heat Treatment Furnace: Unique muffler technology to avoid leakage after long-term usage, uniform temperature control and atmosphere control.

Operating Temperature of the Heat Treatment Furnace: 200-1050 deg. C.

Options of the Heat Treatment Furnace: Temperature profiling system, computer monitoring system, atmosphere monitoring system and ultrasonic belt cleaning system.

Spcification

Features of the Heat Treatment Furnace: Unique muffler technology to avoid leakage after long-term usage, uniform temperature control and atmosphere control.

Operating Temperature of the Heat Treatment Furnace: 200-1050 deg. C.

Options of the Heat Treatment Furnace: Temperature profiling system, computer monitoring system, atmosphere monitoring system and ultrasonic belt cleaning system.

Spcification

| PART | FUNCTION | NOTE |

| Loading Machine | Autommatic Loading of Screws | Optional |

| Front Washing Machine | Wash Workpiece Before Heat | Optional |

| Quenching Furnace | Quenching/Carburizing | Main Part |

| Quenching Tank | Quenching | Main Part |

| Washing Machine | Wash Workpiece After Heat | Optional |

| Tempering Furnace | Tempering | Main Part |

| Drying Machine | Dry Workpiece | Optional |

| Blackening Groove | Blackening Surface Process | Optional |

WHO WE ARE

Thanks to the over 20 years of experiences in designing and manufacturing high level of metal forming machines, all equipment RONEN proposes you is based on high standard of quality and reliability, that can assure you final total quality of processes, products and reputation in the market.

RONEN offered specialized spring making machines, stamping hardware machines, hot forged products machines, induction heating machines and services to the steel industry, specifically helping hundreds of customers all over the world to create profitable and efficient production processes in a safe environment.

Our Certificates And Exhibitions

Our Partner Show

Our Partner Show

After-sales Service

√ 12 months warranty

√ Assistance on purchasing related equipment/products

√ Free training course onsite

√ Engineers are available for overseas service.

√ Technical support at any stage via any communication form

FAQ

1. -Can your machinery produce non-standard parts?

-Yes, we can. Our machinery can produce non-standard parts, at the same time, we can also custom the machine according to your parts drawings.

2. -Does your factory have customers in our country?

-We have rich experience in export. Europe, Asia, Africa, North America, South America, Oceania, all have our customers.

3. -Can you provide commissioning video and samples?

-Sure. We will update the information (photos, videos, etc.) with you during and after commissioning, and send samples. The shipment will be arranged only after you confirm it is correct.

-Yes, we can. Our machinery can produce non-standard parts, at the same time, we can also custom the machine according to your parts drawings.

2. -Does your factory have customers in our country?

-We have rich experience in export. Europe, Asia, Africa, North America, South America, Oceania, all have our customers.

3. -Can you provide commissioning video and samples?

-Sure. We will update the information (photos, videos, etc.) with you during and after commissioning, and send samples. The shipment will be arranged only after you confirm it is correct.