Basic Info.

Model NO.

SGL-J-60/80/100/120

Type

Electric Holding Furnace

Usage

Steel Molding

Fuel

Electricity

Scope of Application

Industrial Tube/ Sanitary Pipe Annealing

Material Applied

300 Series Austentite,Dual Phase Steel and Ect.

O.D. Range

6-114 mm

Thickness

0.38-12.0

Temperature

1050-1200

Production Speed

1-7 M/Min

Power(W)

60-300 Kw

Dimension(L*W*H)

Customized

Control Type

PLC

Heating Type

Induction Heating

Warranty

1 Year

After-Sales Service

Engineers Service Machinery Overseas Available

Lead Time

45-90 Days

Standard

ASTM, DIN, ISO, GB and etc.

Color

Customized

Transport Package

Waterproof Film and Pallets

Specification

Customized

Trademark

SEKO

Origin

China

HS Code

8514400090

Production Capacity

20 Sets Per Year

Packaging & Delivery

Package Size

6.20cm * 1.20cm * 2.00cm

Package Gross Weight

2500.000kg

Product Description

Product Details

√ Supplier Audit Programs

√ Product Inspection before Delivery

√ Lab Testing Supported

√ 20-year Industry Professional Experiences

√ Customer Oriented Technology Team

√ Timely Response After-sales Backup

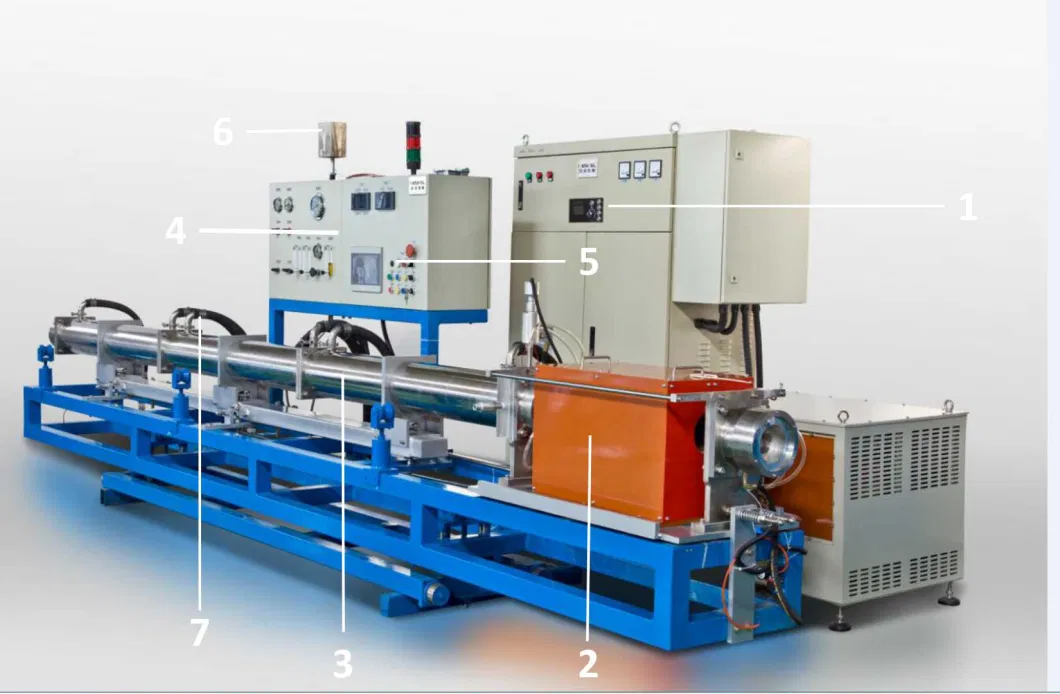

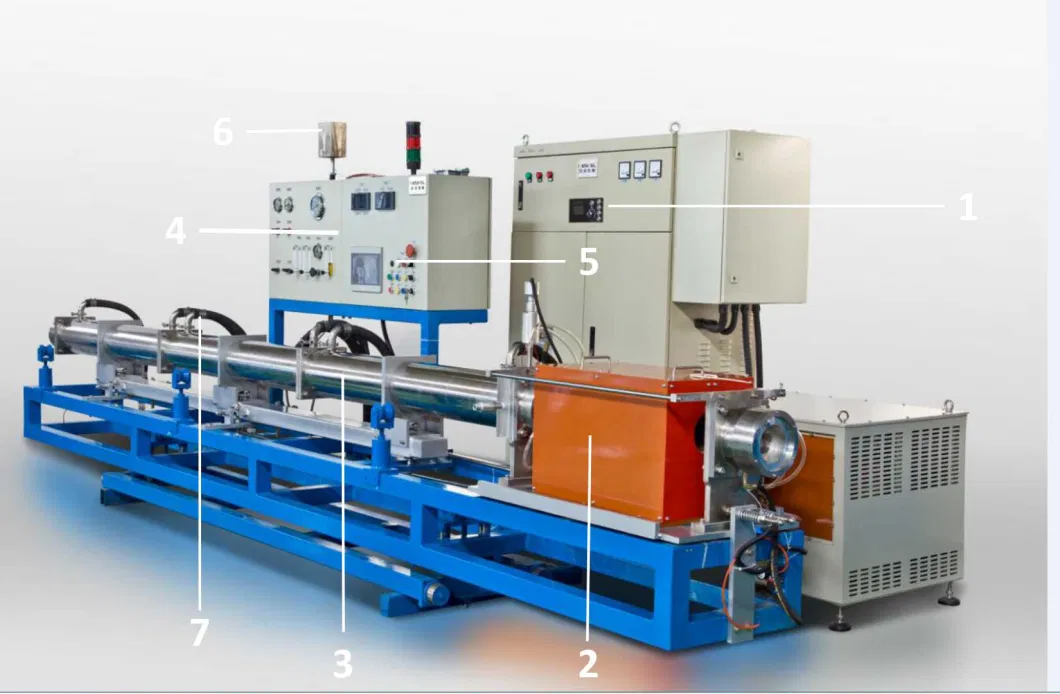

1.Heating power system

2.Induction coil

3.Cooling tunel

4.Temperature control system

5.Electrical control system

6.Hydrogen burning device

7.Recyvled water cooling system

Process Flow

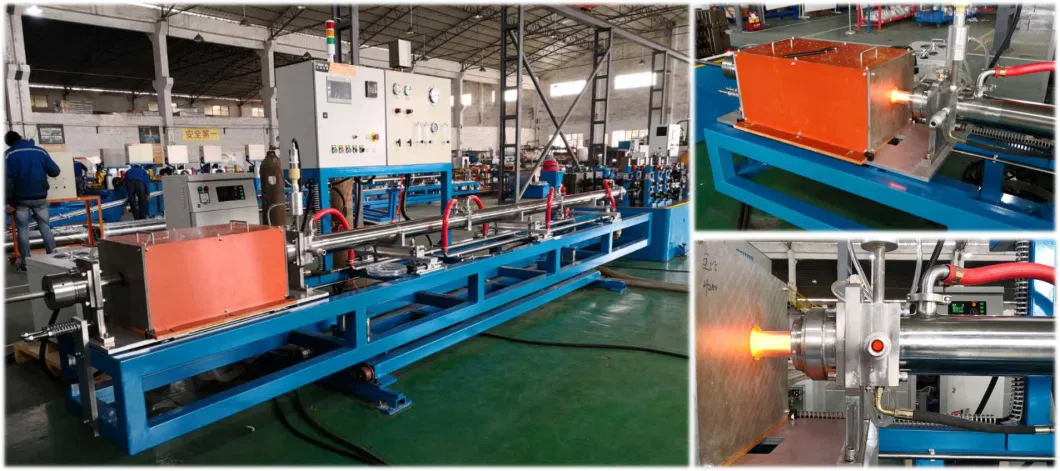

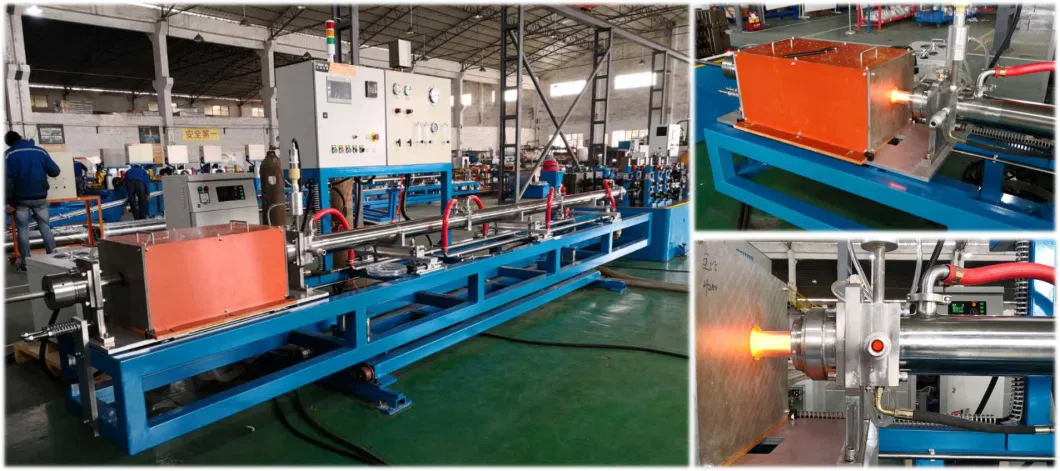

Bright Annealed (BA) pipe is produced by heat-treating (annealing) steel with an environment friendly bright annealing machine induction heat treating furnace. After heat-treatment, the steel has a reflective, mirror-like appearance, but may also have some imperfections and cloudiness. BA stainless steel can be buffed to attain a more reflective finish, and is often specified for applications where a highly reflective surface is desired.

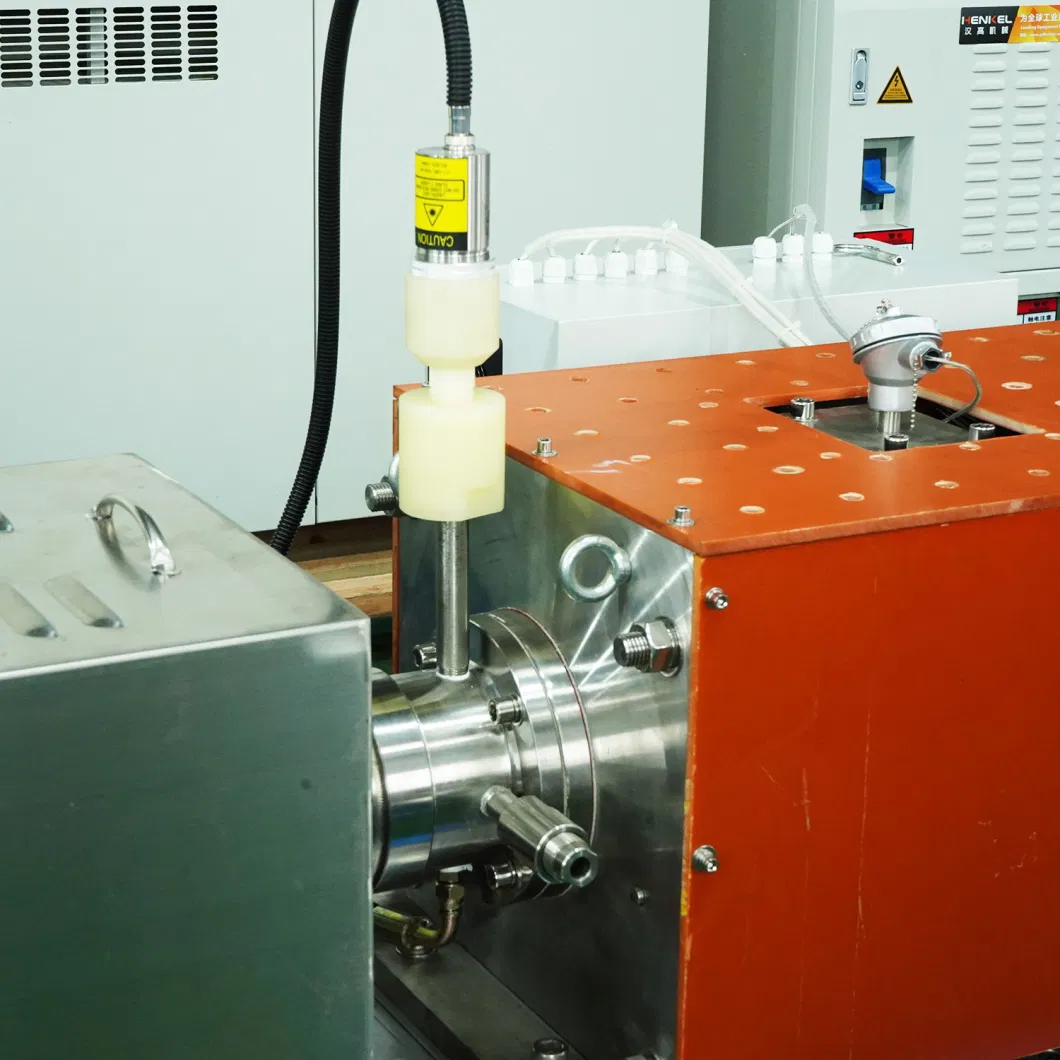

On-Line Fixing & Fusing (Anealing) equipment can heat the stainless steel welded pipeto 1050°C then cool it to the temperature lower than 100 °C under the protection of hydrogen.The heating power supply of the intermediate ferquency induction is the newest DSP+IGBT structure.With DSP digital control system,there are self protection and self diagnostic functions.With small volume,it heats pipes rapidly and efficiently with energy-saving and low-waste features.The especially developed inducer designed according to the features of stainless steel can save 15%-20% energy in contrast of other products of the same class.Using hydrongen as of gas every minute.

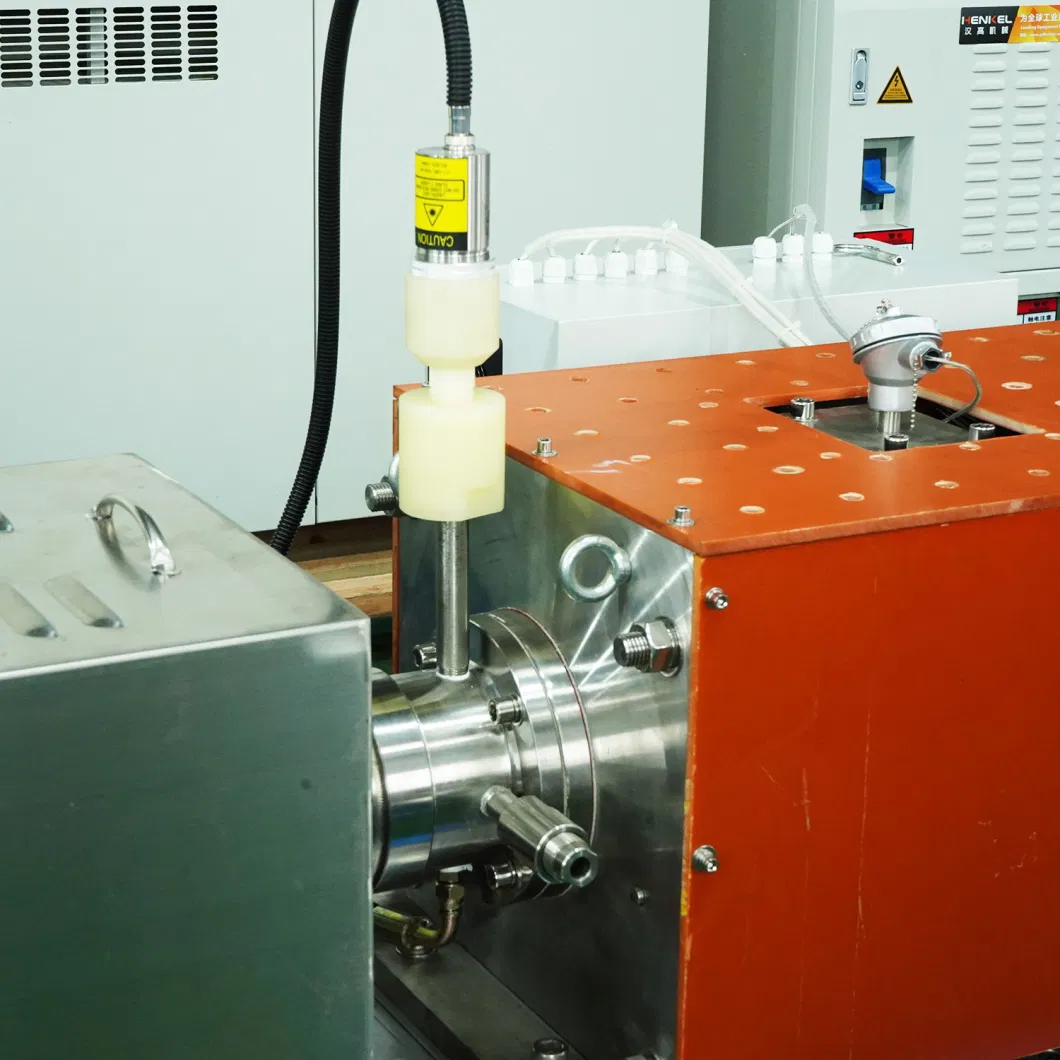

Water Pressure /Atmosphere pressure monitoring

Excellent Designed Air sealing spare parts

Thermocouple temperature measurement

Function

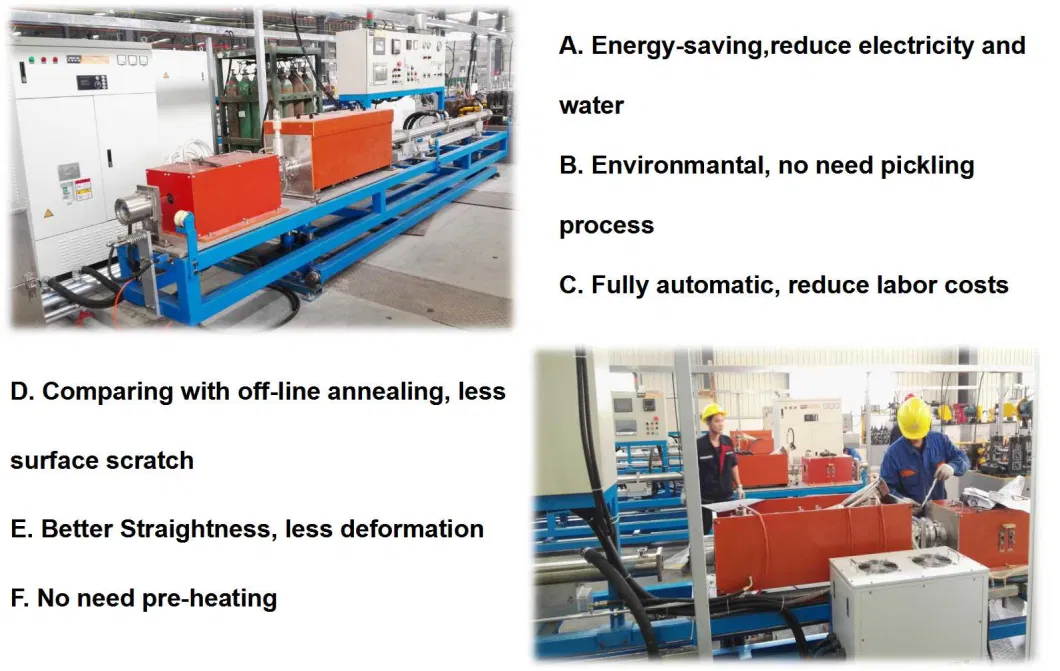

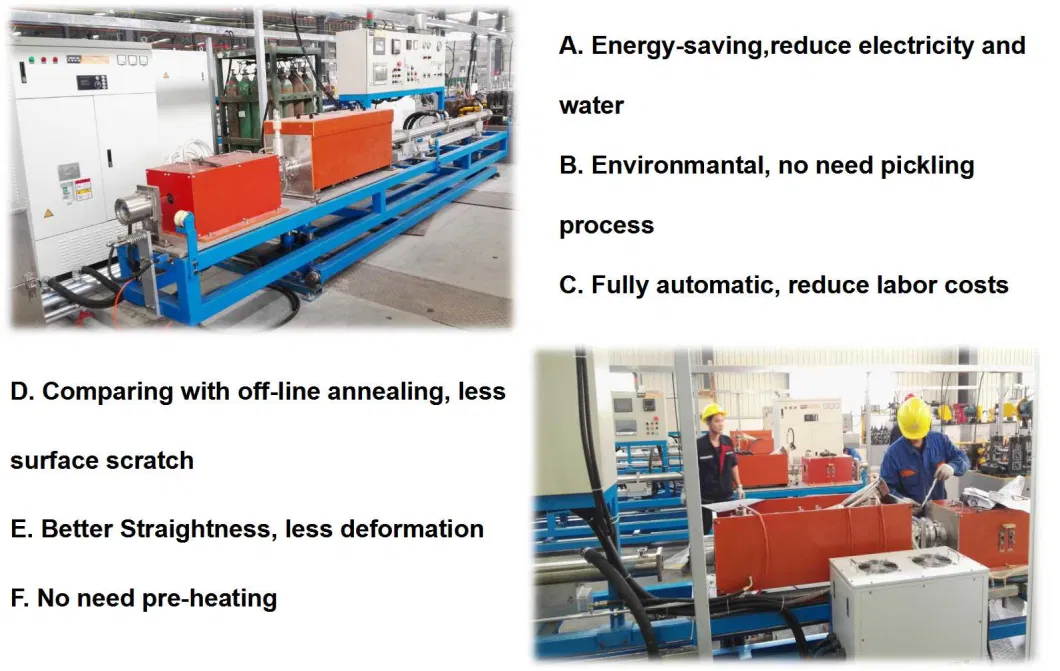

1. Reduce the hardness of steel pipes, improve the plasticity, to facilitate cutting machining and cold deformation.

2. Fine grains and homogeneous steel organization and composition, to improve the performance of steel, also to make preparation for the heat treatment.

3. Remove the residual internal stress in steel, to prevent deformation and cracking.

Our Feature

Application

SEKO Machinery Security Induction Heating Oven Bright Annealing Equipment for TIG Welding specializes in industrial usage, like HVAC pipe fittings, sanitary tubes, water pipes, valve pipe fittings, petrochemical pipes, chemical industry, medicine industry, wine-making industry, petroleum industry, food industry, automobile industry, paper making industry, air-condition making industry and so on. Products dealed with our tube mill could reach ASTM, DIN, ISO, GB and JIS standard.

About SEKO

Guangdong Shunde Seko Machinery Co., Ltd. founded in 2009. We are an industrial stainless steel welded pipe making machine manufacturer, with 20 year experience, which integrates design, research and development, manufacture, sale, after-sale service and other supporting service. By virtue of its excellent credit, high performance products and considerate service, our company has won a large group of loyal customers and is recognized by its peers and the authoritative organizations highly. Its products are exported to Dubai, Russia, India, Thailand, Pakistan, Vietnam and ect..

FAQ

1. Which countries your products are exported to?

Our products are sold all over the world and with related certifications.

2.How about the warranty?

All our products have one year quality warranty, during the warranty time, the spare parts replacement is free. And we provide life long time technical support and other assistance.

3.How to install your machine?

Usually speaking, engineers will be sent to your factory to help to install and adjust the machines. We also have paper installation instructions and videos, teaching you till you command it.

4. Which export port you use?

Any China ports. Commonly, we will use Shenzhen port. But it can be appointed as you like.

5. How about the payment terms and delivery time ?

Payment terms for small machines: 100% T/T/ Western Union/Cash in advance.

The big machines and big amount: 40% deposit, 60% before shipment (we will shoot total delivering process for customer's confirmation) and the related papers. You can pay by T/T,L/C, Western Union or other ways.

The machine delivery time is within 45-90 days.

6.Is your goods with ISO9001 or CE certificate ?

Yes, all our goods has ISO certificate. All machines are high quality goods.

7.What is your nature of your company:dealer or factory ?

We are manufacturer with a big factory ,warmly welcome to visit our factory and contact us.

| Type | Cooling Type | Adjustable power output range | Rated power current | Motor Power (KW) | Max relative humidity | Size(L*W*H)(m) |

| SGL-J-60 | water cooling | 1%-100% | 105A | 60 | 95% | Customized |

| SGL-J-80 | water cooling | 1%-100% | 140A | 80 | 95% | Customized |

| SGL-J-100 | water cooling | 1%-100% | 140A | 100 | 95% | Customized |

| SGL-J-120 | water cooling | 1%-100% | 175A | 120 | 95% | Customized |

| SGL-J-160 | water cooling | 1%-100% | 165A | 160 | 95% | Customized |

√ Supplier Audit Programs

√ Product Inspection before Delivery

√ Lab Testing Supported

√ 20-year Industry Professional Experiences

√ Customer Oriented Technology Team

√ Timely Response After-sales Backup

1.Heating power system

2.Induction coil

3.Cooling tunel

4.Temperature control system

5.Electrical control system

6.Hydrogen burning device

7.Recyvled water cooling system

Process Flow

Bright Annealed (BA) pipe is produced by heat-treating (annealing) steel with an environment friendly bright annealing machine induction heat treating furnace. After heat-treatment, the steel has a reflective, mirror-like appearance, but may also have some imperfections and cloudiness. BA stainless steel can be buffed to attain a more reflective finish, and is often specified for applications where a highly reflective surface is desired.

On-Line Fixing & Fusing (Anealing) equipment can heat the stainless steel welded pipeto 1050°C then cool it to the temperature lower than 100 °C under the protection of hydrogen.The heating power supply of the intermediate ferquency induction is the newest DSP+IGBT structure.With DSP digital control system,there are self protection and self diagnostic functions.With small volume,it heats pipes rapidly and efficiently with energy-saving and low-waste features.The especially developed inducer designed according to the features of stainless steel can save 15%-20% energy in contrast of other products of the same class.Using hydrongen as of gas every minute.

Water Pressure /Atmosphere pressure monitoring

Excellent Designed Air sealing spare parts

Thermocouple temperature measurement

Function

1. Reduce the hardness of steel pipes, improve the plasticity, to facilitate cutting machining and cold deformation.

2. Fine grains and homogeneous steel organization and composition, to improve the performance of steel, also to make preparation for the heat treatment.

3. Remove the residual internal stress in steel, to prevent deformation and cracking.

Our Feature

Application

SEKO Machinery Security Induction Heating Oven Bright Annealing Equipment for TIG Welding specializes in industrial usage, like HVAC pipe fittings, sanitary tubes, water pipes, valve pipe fittings, petrochemical pipes, chemical industry, medicine industry, wine-making industry, petroleum industry, food industry, automobile industry, paper making industry, air-condition making industry and so on. Products dealed with our tube mill could reach ASTM, DIN, ISO, GB and JIS standard.

About SEKO

Guangdong Shunde Seko Machinery Co., Ltd. founded in 2009. We are an industrial stainless steel welded pipe making machine manufacturer, with 20 year experience, which integrates design, research and development, manufacture, sale, after-sale service and other supporting service. By virtue of its excellent credit, high performance products and considerate service, our company has won a large group of loyal customers and is recognized by its peers and the authoritative organizations highly. Its products are exported to Dubai, Russia, India, Thailand, Pakistan, Vietnam and ect..

FAQ

1. Which countries your products are exported to?

Our products are sold all over the world and with related certifications.

2.How about the warranty?

All our products have one year quality warranty, during the warranty time, the spare parts replacement is free. And we provide life long time technical support and other assistance.

3.How to install your machine?

Usually speaking, engineers will be sent to your factory to help to install and adjust the machines. We also have paper installation instructions and videos, teaching you till you command it.

4. Which export port you use?

Any China ports. Commonly, we will use Shenzhen port. But it can be appointed as you like.

5. How about the payment terms and delivery time ?

Payment terms for small machines: 100% T/T/ Western Union/Cash in advance.

The big machines and big amount: 40% deposit, 60% before shipment (we will shoot total delivering process for customer's confirmation) and the related papers. You can pay by T/T,L/C, Western Union or other ways.

The machine delivery time is within 45-90 days.

6.Is your goods with ISO9001 or CE certificate ?

Yes, all our goods has ISO certificate. All machines are high quality goods.

7.What is your nature of your company:dealer or factory ?

We are manufacturer with a big factory ,warmly welcome to visit our factory and contact us.