Basic Info.

Product Description

Excellent performance

10% higher work efficiency with 10% lower consumption.

1. Wide range and high density(75D example)

Weft yarn range from 10D-1800D,weft yarn range from 10D-300D, and yarn denisty can achieve 197 pick/inch.

2. High speed

Design speed is 700rpm;Dobby shedding( 16 pcs frame):600-650rpm;

3. Low maitenance cost

Much more convenient maintenance operation, durable oil and filters to make longer maitenance period, 50% less expense

Cam Shedding Specifications| HW-8010 | ||

| No. | NAME | Type and performance specifications |

| 1 | Wall board | We adopts HW-8010 special heavy enhanced, according to TSUDAKOMA Drawing,HT220-230 standard material, large CNC precision machining. |

| 2 | Gear in the large box | AdoptingTaiWan(TTG)gear,ultra-quite,wear-resistant,low vibration and high precision. |

| 3 | Bearing in the large box | Bearing in the large box is swedish SKF, Bearing out of the large box made in japan. |

| 4 | Beating up shaft | Adopt special treatment of solid beating up shaft, centralized oil lubrication in the support sleeve, add in weft counter weightbalancesystem(Haijiapatent:201220718493.9), optimization of beating up angle, the beating up more powerful and stable, cloth smooth. |

| 5 | Slay | SUS304 stainless steel reinforced and polishing processing slay at the top brand in China, achieve cloth smooth. |

| 6 | Stripe | Tianqi stripe, For 102 double stick, strengthening take-up. |

| 7 | Plastic stocks | New type and high quality plastic stocks. |

| 8 | Beam | A number of optimization design on the basis of TSUDAKOMA ZW-410, the beam before and after the five angle pipe, steel material supply, before and after the beam with thickened angle.Especially before the beam on Haijia, unique design, draws on the advantages of air jet loom beam, making solid beating up shaft is more stable. |

| 9 | Electronic clip yarn | Electronic clip yarn. |

| 10 | Suction pipe | ∮76mm,thickness 6mm,sus304 stainless steel. |

| 11 | Cross beam | Heavy and lengthen treatment. |

| 12 | Tension spring | ∮12mm. |

| 13 | Panel | HW-8010 Special type. |

| 14 | Let-off and take-up device | Domestic electronic let-off and take-up. |

| 15 | Temple bar,guide | HJ-851 Special type ,3mm stainless steel. |

| 16 | Temple | Five ring three rows of fine needle puncture (0.3mm) under the pressure of Temple (made fine denier fabric cloth smooth) South Korea Renhe or Jilong brand. |

| 17 | Leno parts | Taiwan production assembly (slide seat:Stainless steel, low noise ear wire assembly, running smoothly, long service life). |

| 18 | Press roll | New press fabric service,press roll 40#,equal tension take-up. |

| 19 | Main motor | The Haijia special power of 3.0KW red flag.Save electricity,start fast,low noise,little park,long life and other advantages(self-purchased Japan NACHI bearing). |

| 20 | Electronic control system | Xinliao NingBo Brand..(electronic control,electronic let-off and take up,feeder triad control ,with 7 inch electronic display). |

| 21 | Measuring | Adopting double jet Electronic length measuring .Adopting double Electronic measuring. |

| 22 | Light detection weft | Light detection weft, plus plug signal amplifier. |

| 23 | Code | Electronic. |

| 24 | Plunger | Shutai ceramic plunge |

| 25 | Spring | Japan AWA spring |

| 26 | Nozzle | Korea MDH |

| 27 | One way valve | Japan AWA valve |

| 28 | Oil seal | Made in Taiwan |

| 29 | Cutter parts | Taiwan bearing,scissors,scissors spring,improve efficiency. |

| 30 | Suction motor | Electronic suction motor HB(0.5kw) |

| 31 | Stabilized tank | Double filter,bucket type. |

| 32 | Take heald level | American DuPont material production, wear, long service life. |

| 33 | heald frame | Haijia designed high quality strengthend frame Customer can match by themselves. |

| 34 | Painting | TSUDAKOMA yellow color, two times over the primer, topcoat, special paint production line, improve the anti rust effect. |

| 35 | The whole machine of Stainless steel screw | Taiwan dongming SUS304 stainless steel screw,not rust |

| 36 | Stainless steel screw | Jin Yi brand in Taiwan |

| 37 | Waterproof device | Thickened waterproof curtain, TSUDAKOMA style transparent waterproof cover plate. |

| 38 | False twist spindle | Pull type |

| 39 | Weft stand | Double nozzle standard weft stand. |

| 40 | Oil supply | Centralized oil supply including beating up shaft and shedding parts |

| 41 | Swing degree | null |

| 42 | Casting | Identify quality supplier, according to the standard drawings, guarantee the material and weight.. |

| Haijia factory main material difference than other factories. | ||||||

| NO. | ITEM | OTHERS | PRICE | HAIJIA | PRICE | COST PRICE DIFFERENCE(6916¥/set) |

| 1. | Outside wall board | HT200,made in wangtai town | 6000¥/Ton | HT250,made in henan province,china largest supplier for cast,same with TSUDOKOMA | 9500¥/Ton | (11000¥-6000¥)*394KG/1000=1970¥/set |

| 2. | Middle wall board | HT200,made in Wangtai town | 5000¥/Ton | HT250,made in Henan province,china largest supplier for cast,same with TSUDOKOMA | 8800¥/Ton | (8800¥-5000¥)*160KG/1000=608¥/set |

| 3. | Other HT material | HT150,made in wangtai town | 4000¥/Ton | HT200,made in henan province,china largest supplier for cast,same with TSUDOKOMA | 4800¥/Ton | (4800¥-4000¥)*514KG/1000=411.2¥/set |

| 4. | Ductile iron | QT420,made in wangtai town | 5000¥/Ton | QT450,made in henan province,china largest supplier for cast,same supplier and standard with TSUDOKOMA | 5800¥/Ton | (5800¥-5000¥)*542KG/1000=433.6¥/set |

| 5. | Steel pipe | Seam | 3100¥/Ton | Seamless | 5950¥/Ton | (5950¥-3100¥)*(63.38KG+63.38KG)/1000=361.3¥/set |

| 6. | Bearings out of wall board | Made in china | 1190¥/set | Japan NSK or NACHI | 3080¥/set | 560¥/set |

| 7. | Pickling and phosphate | No | 0 | have | 2200¥/set | 2200¥/set |

| 8. | Zinc rich primer | No | 0 | have | 253.4¥/set | 253.4¥/set |

| 9. | Epoxy primer | have | 0 | have | ||

| 10. | Epoxy paint | have | 0 | have | ||

| 11. | Ss bolts | Dahua brand,made in shanghai | / | Dongming or Jinyi brand,made in taiwan | / | 120¥/set |

| 12. | Ss oiling mouth | Ss 201 material | / | Ss 304 material | / | / |

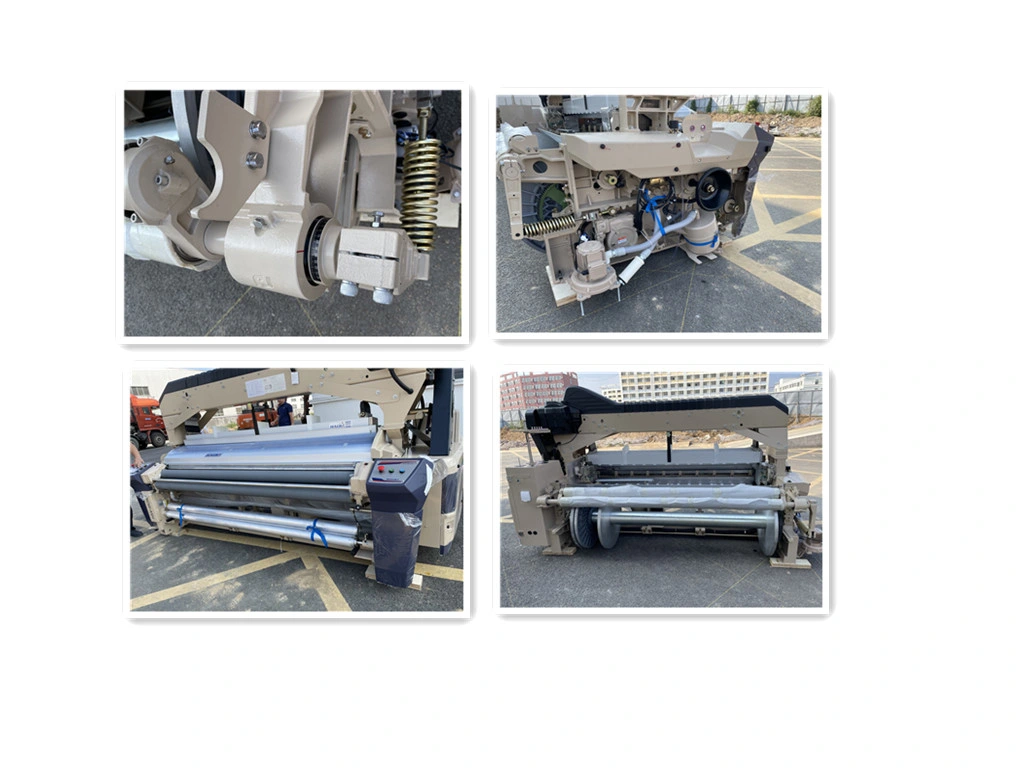

Production Details Show

Workshop Introduction

Workshop IntroductionThree Dimensions Warehouse

The company is equipped with an automated three-dimensional warehouse, which uses computers to accurately manage the goods information, reducing possible errors in the process of storing goods and improving work efficiency. At the same time, the three-dimensional automated warehouse realizes motorization in the transportation of goods in and out of the warehouse, which is safe and reliable in handling goods, and reduces the damage rate of goods in the process of handling.

Advanced Processing Workshop

Advanced Processing Workshop The company is equipped with advanced CNC equipment, high-precision imported processing center, and adopts information management methods to achieve independent precision machining of precision parts of key parts of the loom. The processing accuracy of key parts and components reaches 0.01mm,greatly improving the whole machine Stability and startup efficiency.At the same time, we have introduced MES system to collect the processing information and equipment operation of all equipment in the processing workshop, so that managers can more intuitively understand the output of the processing workshop and effectively shorten the production cycle.

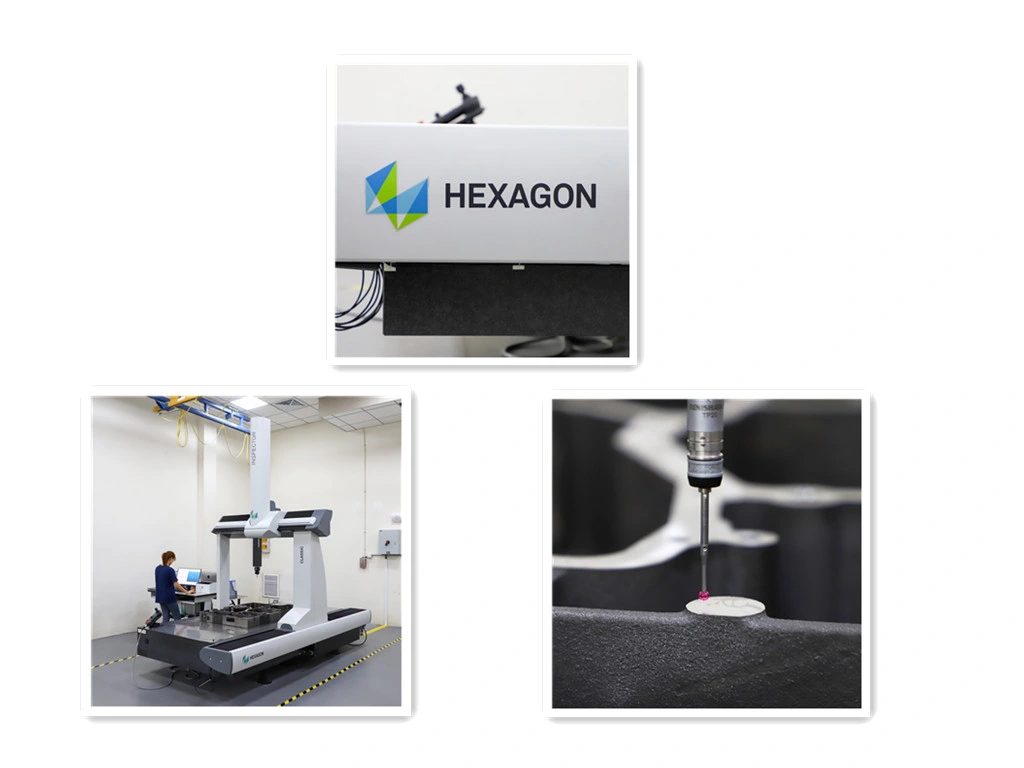

Quality Detection Workshop

The company adopts advanced calibration and testing equipment to ensure the qualified rate of products produced in each process and strictly control the quality fluctuation, so as to ensure the product quality of the whole machine. Improve the production process through inspection, reduce the quality cost and enhance the comprehensive competitiveness of products.

The World's Advanced Electrophoretic Spraying Process

Advanced Assemble Workshop

On the basis of the whole machine assembly line, the company introduced Siemens to intelligentize the loom assembly, and realized the "mobile people do not move" production mode, that is, the pulsating production mode. Through strict quality management, fine differentiation of assembly process flow, fastening connectors with special tools with fixed torque, and strict inspection of production facilities, the quality of the overall loom is improved.

Haijia Machines' Working Cass in Customer factory

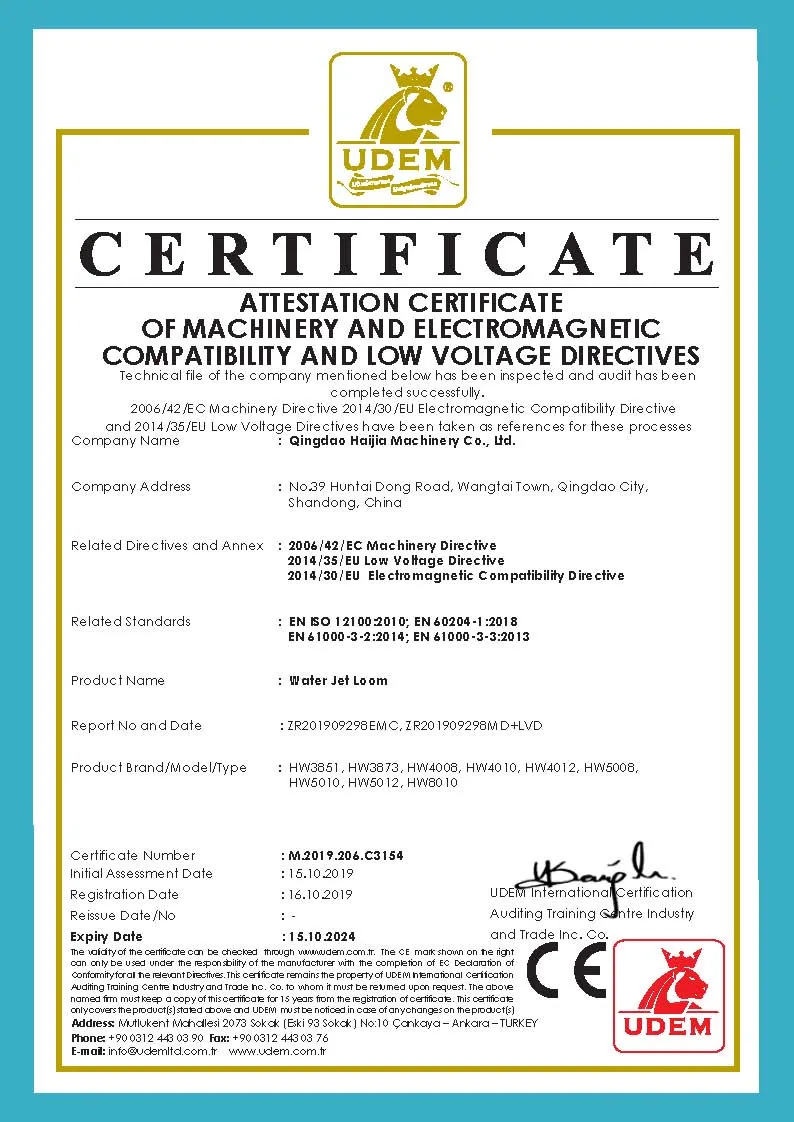

Certification of HAIJIA Equipment

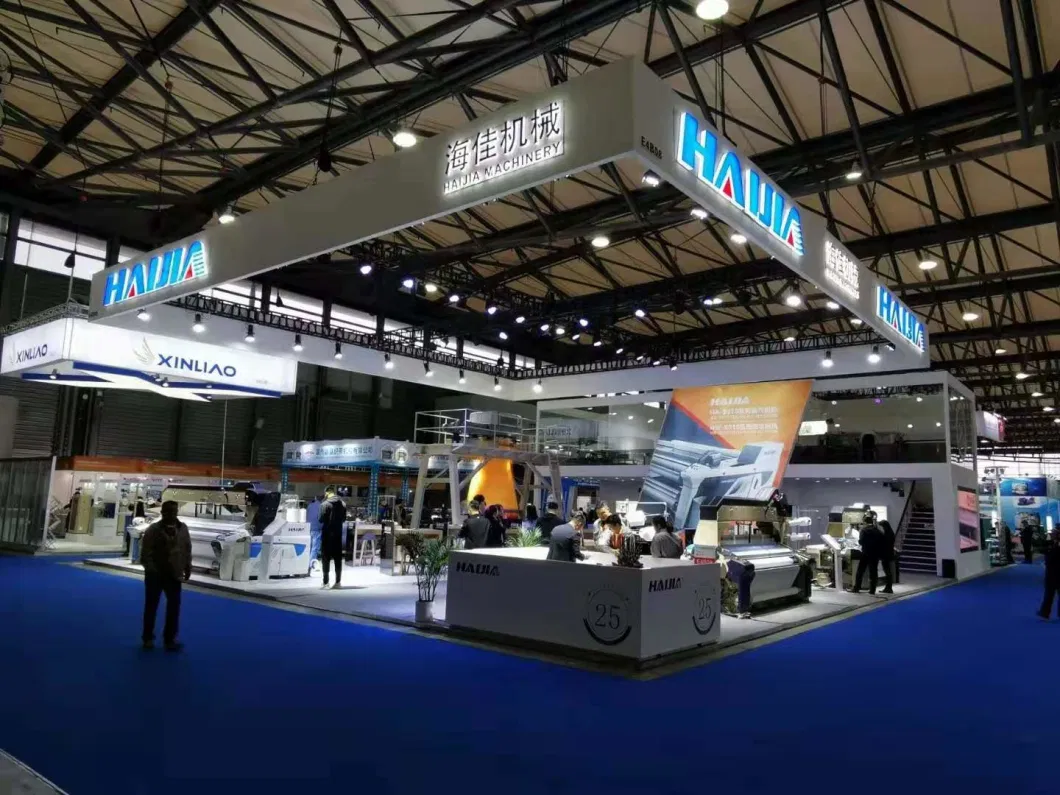

HAIJIA On Shanghai Exhibition

FAQ

1: What kind terms of payment can be accepted?

A: For terms of payment, L/C, T/T, D/A, D/P could accepted

2: What certificates are available in Machinery?

A: For the certificate, we have CE,ISO

3: What about the delivery time?

A: 30-45 days after receiving the deposit.

4: What about the warranty time?

A: 12 months after shipment.

5. What about the Minimum Order Quantity?

A: The MOQ is 6 pcs.

Connect to us

Mr.Othman

QINGDAO HAIJIA MACHINERY CO.,LTD

ADD:NO.39 HUANTAI DONG ROAD,WANGTAI TOWN HUANGDAO QINGDAO CITY CHINA