- Overview

- Product Description

- Product Parameters

- Company Profile

- Certifications

- FAQ

Basic Info.

Model NO.

TIG Wire

Max Current at 100%

3A AC

Drive

4 Toothed Rolls

TIG

Tungsten Inert Gas

Weight

Approx 16 Kg

Specification

Approx 610 mm*236*mm*420 mm

Origin

China

Packaging & Delivery

Package Size

61.00cm * 24.00cm * 42.00cm

Package Gross Weight

19.000kg

Product Description

The automatic wire feeding pipe is directly led out from the inside of the welding gun, and the narrow working

condition does not hinder the operation.

The wire feeding efficiency is increased by 40%, the perfect fish scale pattern can be achieved by adjusting

the welding parameters.

the welding parameters.

| Technical Data | |

| Supply Voltage | 230V AC / 50/60Hz |

| Wire Feed Rate | 0. 1m/min - 8.0m/min |

| Drive | 4 Toothed Rolls |

| Wire Diameter | 1.0mm~1.6mm |

| Protection Pating | IP21 |

| EMC Class | A |

| Max Current at 100% | 3A AC |

| TIG | Tungsten Inert Gas |

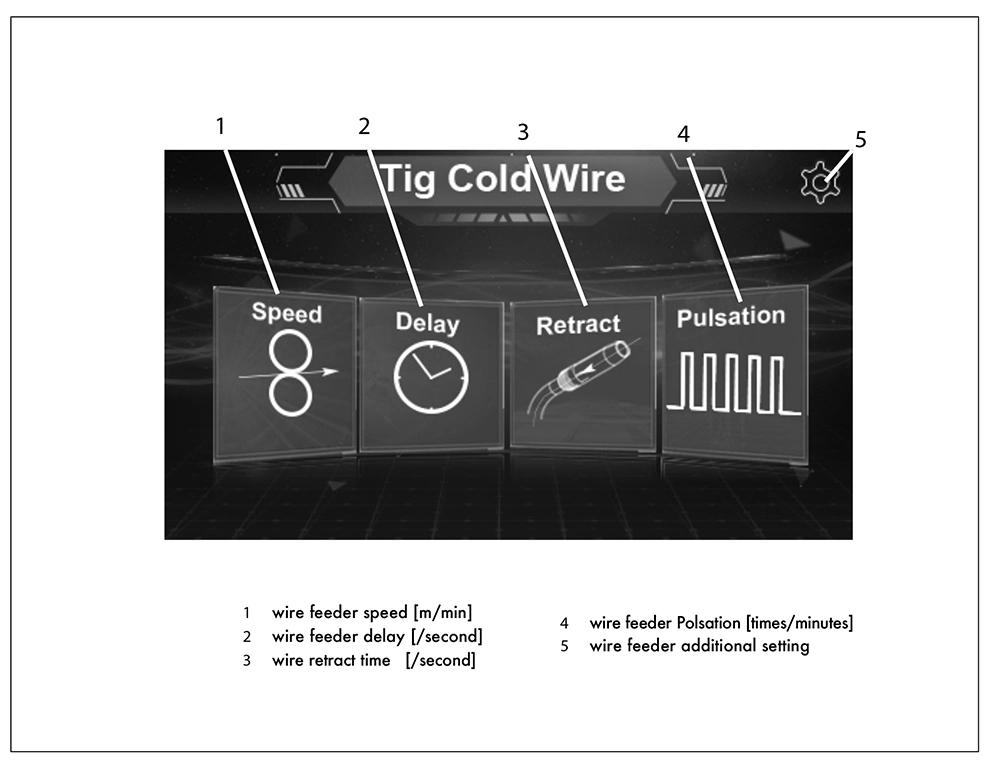

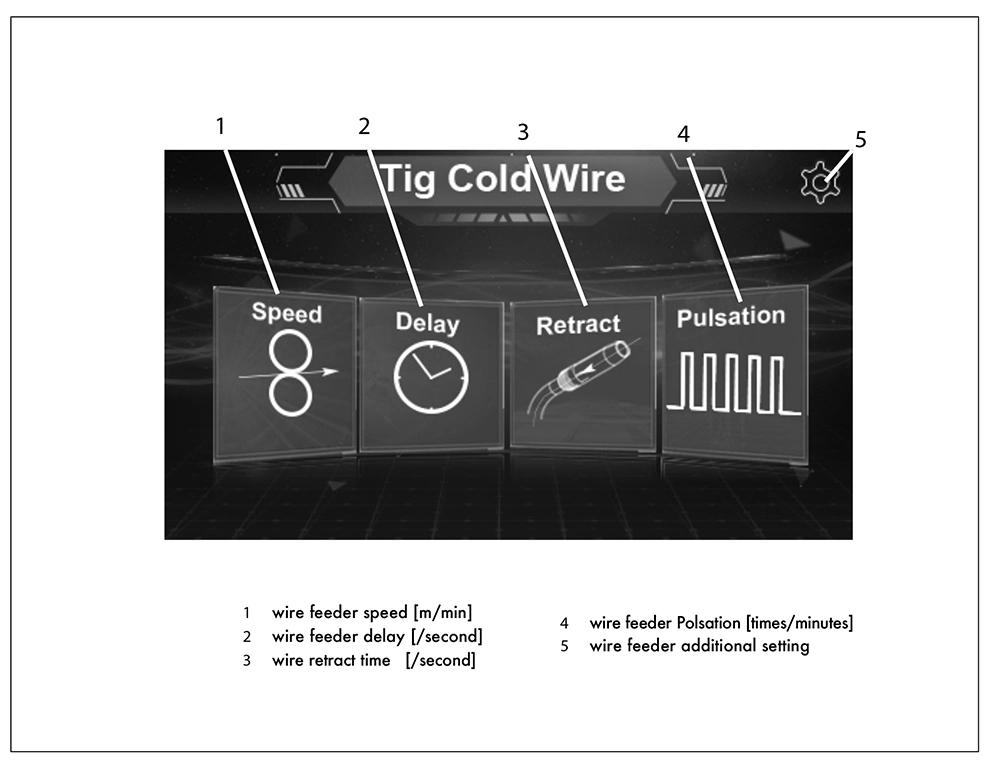

Functional description

The TIG cold-wire feeder is single parts of the welding system. The wire required for TIG welding is delivered through the manual welding torch (2).

The wire is fed constantly to the TIG arc via a four-roll drive. The TIG arc is produced by an TIG manual welding torch (2) and a power source (3).

The components need for welding, such as welding current, shielding gas and coolant, are connected to the power source (3). The required welding wire depends on the material to be welded and is taken from the intergrated wire spool.

Putting into operation

Atmospheric charging between the welding device and cold wire feeder system can be prevented by a potential equalisation cable (8). The corresponding connection cable is included in the scope of delivery for new devices. For devices that are already in use, this connection cable is available as a spare part and can be retrofitted at any time.

The assembly of the potential equalisation cable (8) is described in the assembly instruction. The wire spool seat with a brake is used to hold standardised welding wire spools with a maximum weight of 16kg and a maximum diameter of 300mm.

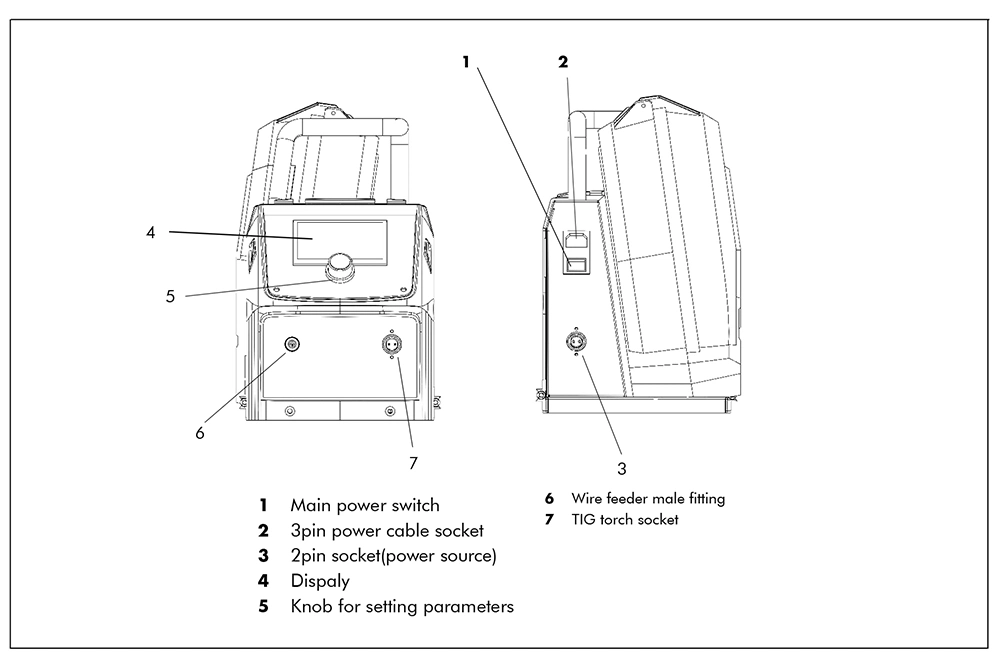

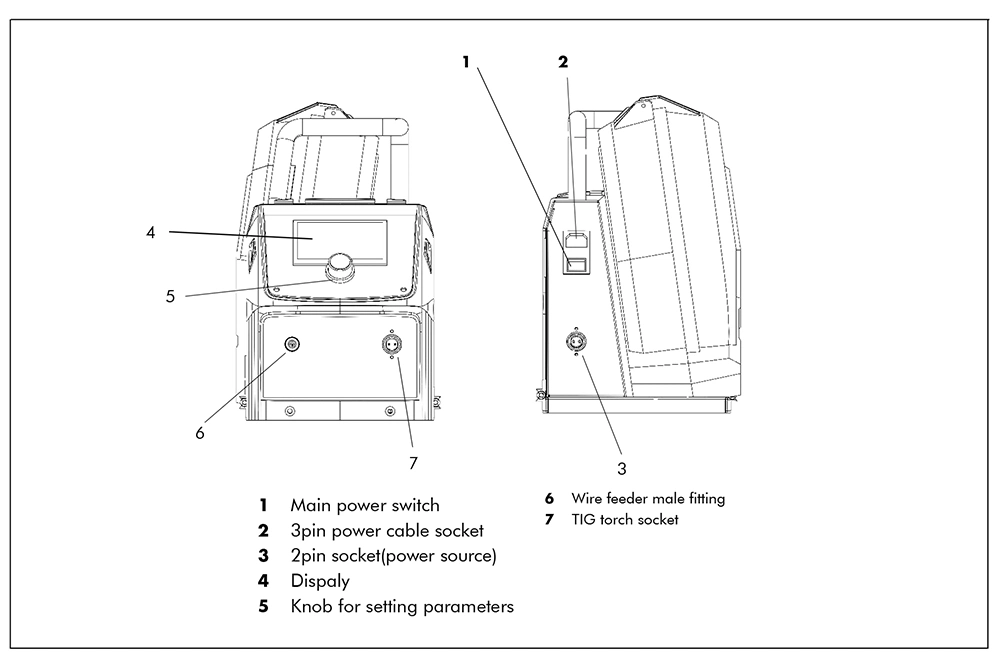

Switching on the device

Switching the TIG cold wire feeder use main switch on the back.

Connecting the intermedia cable

(Only use the intermedia cable desgin for the TIG cold wire feeder.)

1. Connect the intermedia cable plug 4 to the cold wire feeder socket 5;

2. Connect the intermedia cable plug 2 to the power source switch socket.

2. Connect the intermedia cable plug 2 to the power source switch socket.

Connecting the torch cable assembly

Only use intermediate cable assemblies and torch cable assemblies designed for the TIG cold wire pro. Applies to liquid-cooled welding torches only!

1. Connect the torch wire connector to the wire feeder machine adaptor plug items 2; 2. Connect the torches control wire lead connector to the wire feeder socket items 5.

Feeding in the wire

1. Open the cover on the TIG cold-wire feeder.

2. Fold both of the pressure levers (1) forwards and open the pressure rolls (2) .

3. Untie the start of the wire from the wire spool and deburr it at the front end.

4. Insert the wire through the liner (5) over the drive rolls (4) into the central socket (3) .

5. Close the pressure rolls (2) and fold the pressure levers (1) back into the vertical position.

6. Feed the wire through the cable assembly by pressing either the wire feed button on the front control panel or the torch trigger.

2. Fold both of the pressure levers (1) forwards and open the pressure rolls (2) .

3. Untie the start of the wire from the wire spool and deburr it at the front end.

4. Insert the wire through the liner (5) over the drive rolls (4) into the central socket (3) .

5. Close the pressure rolls (2) and fold the pressure levers (1) back into the vertical position.

6. Feed the wire through the cable assembly by pressing either the wire feed button on the front control panel or the torch trigger.

Replacing the drive rolls

Connecting the torch and the welding device

The wire feeder can be controlled using an appropriate standard torch. The welding power source can be optionally triggered by the start welding signal from the wire feeder. The signal occurs via back side of the wire feeder socket. 4-trigger with torch for controlling the tig wire feeder function.

On the mode 2T, the T4 button wire feed will start feeding wire process in any time. On the mode 2T, the T2 button will ignition the power source for arcing. Once the material was melt, pressing T4 button to contiune wire feeding. Once release the T4 button, signal for arcing and wire feeding will stop together.

On the mode 4T, press the T2 to starting the arc , press T4 switch one times, wire will be automatic feeding and follow the parameter of the pre setting. Press T4 switch again, signal for arcing and wire feeding will stop together.

This mode is recommended for automated welding as the wire feed and the welding process can be started via one signal. For automatic welding, the welding process is using the separate trigger.

| Product Name | Argon Arc Automatic Wire Feeder |

| Packaging | 1 set/carton |

| Dimension | Approx 610mm*236mm*420mm |

| Weight | Approx 16kg |

| Gross Weight | 20kg |